About us

Located on the southcoast, Liondell Ltd is a family-owned business with a combined 50 years’ experience within the plastics industry. Our expertise in plastic product design has allowed us to introduce our unique attenuation solution.

Our Mission

At the heart of our operations is the unity and values of a family business. This provides us with a unique perspective, where every product isn’t just a mere commodity, but a symbol of our dedication, love, and craftsmanship. Being based on the South Coast not only offers us inspiration from its serene beauty but also keeps us grounded to our humble beginnings.

Our Expertise

Plastic Part Design

Design from a Brief to the Client’s Specifications

At Liondell Ltd, our journey begins with your vision. We take your brief, your ideas, and your specifications, and we transform them into tangible plastic part designs. Our team of skilled designers specialises in understanding and interpreting your requirements, ensuring that your vision is translated into a design that’s both aesthetically pleasing and functionally superior.

Re-design of an Existing Product

Sometimes, innovation isn’t about reinventing the wheel; it’s about making the wheel better. Whether you have an existing product that needs a fresh perspective or an enhancement, we excel at re-designing plastic parts to improve their performance, durability, and aesthetics.

Design of Our Own Products from Concept

Innovation is at the core of everything we do. We don’t just design for clients; we create our own products from scratch. Our in-house design team is constantly brainstorming, conceptualising, and bringing new ideas to life, all while drawing from our extensive knowledge of tool design and moulding.

Efficiency through Integrated Design

What sets us apart is our seamless integration of design with tooling and manufacturing. This means that our product designs are not just creative but also practical and feasible from the get-go. We eliminate the need for secondary checks and ensure a direct transition to tool design and manufacturing.

Product Development

Enhancing Dimensional Integrity and Functionality

Once a product has been moulded, our commitment to quality doesn’t stop. We take the newly created product and subject it to rigorous testing and analysis. Our goal is to further develop and refine it, ensuring dimensional integrity and optimal functionality. This iterative process ensures that our products meet the highest standards.

Mould Tool Manufacture

Global Expertise in Toolmaking

Liondell Ltd take pride in our extensive network of approved toolmaking partners across the Far East, Europe, and the UK. These partners understand our quality requirements and project management methods. This global reach allows us to tap into the best expertise and resources to manufacture molds of exceptional quality.

Injection Moulding

Client-Centric Approach to Development

During the development phases of any new mould tooling, we supply the product to our clients, fostering collaboration and transparency. Our UK-based tooling clients, often moulding companies themselves, appreciate our ability to offer production quantity parts when required.

Efficient Supply Chain

Should tooling remain in the Far East, we can efficiently supply products directly from there, with remarkably quick lead times. This streamlined approach ensures a smooth and rapid transition from design to production, regardless of the geographical location of the manufacturing facility.

At Liondell Ltd, we are your end-to-end partner in plastic part design, development, tooling, and injection moulding. Our expertise and commitment to excellence shine through every stage of the process, delivering innovative solutions that meet your exacting requirements.

Quality is our priority

We invite you to explore our offerings, understand our journey, and be a part of our ever-growing family. With Liondell Ltd, you’re not just choosing a product; you’re investing in a legacy of excellence.

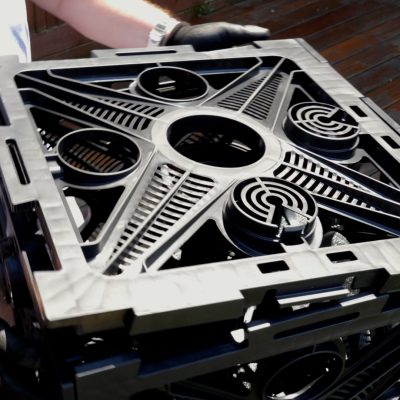

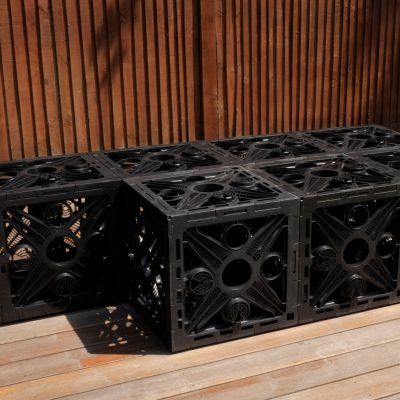

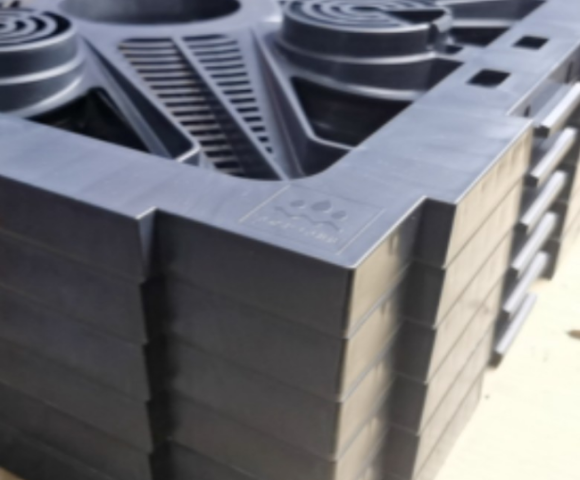

Enquire about the Soakcube

Unlock a new era of drainage solutions with Soakcube! Get started today!